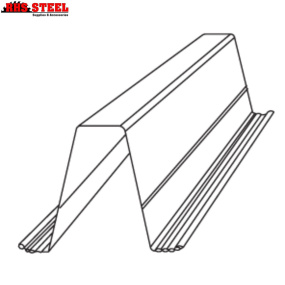

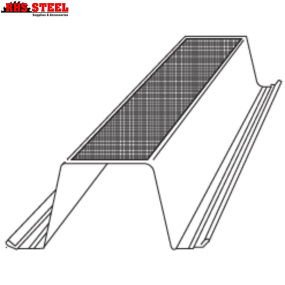

Ceiling Battens - Roof Battens - Top Hat Purlins

Our top hats, ceiling battens and roof battens are suitable for a vast spectrum of residential, commercial, and industrial uses. These offerings are meticulously engineered to serve as secondary components that provide structural support for wall or roof cladding.

Key Product Characteristics and Advantages:

- Versatile range accommodating various construction applications

- Impressive spans enabling diverse installation possibilities

- Extensive selection of product gauges to suit specific needs

- Straightforward and efficient screw fastening mechanism

- Quick and user-friendly installation process

- Offered in both galvanized steel and Zincalume options

- Widest array of products available in the market

- Standard inclusion of rolled safety edges for added safety

Australian Standards

• AS 1170.0:2011, AS 1170.1:2002, and AS 1170.2:2011 - Loading Codes

• AS/NZS 4600:2005 - Cold-formed Steel Structures

• AS 3623:1993 - Domestic Metal Framing

• AS 1397:2011 - Steel Sheet & Strip - G550 MPa Steel

• AS 4055 - Wind Loads for Housing

Material Compatibility

RHS Steel Supplies ceiling battens, roof battens, and top hats should not be utilized in conjunction with exposed metal, stainless steel, lead, copper, concrete, mortar, green, and specific chemically treated timbers. For more detailed information, please reach out to RHS Steel Supplies.

Welding Implications

The process of welding can impact the material characteristics of cold-formed steel products under certain conditions. Furthermore, it may compromise galvanized coatings and reduce material durability. RHS Steel Supplies does not endorse the welding of ceiling battens, roof battens, or top hats.

Cutting Implications

Cutting is feasible, but abrasive discs should be avoided. If cutting is necessary, RHS Steel Supplies recommends the use of a power saw with a steel cutting blade or a power nibbler.

Walking Considerations

• Ceiling battens should never be walked upon or subjected to additional loads.

• Roof battens and top hats can be walked upon with caution during installation and maintenance.

Batten Spacing Implications

Batten spacing must be determined based on factors such as roof sheeting capacity, roof tile spacings, truss spacings, and plasterboard specifications. In scenarios where local wind pressure increases, supplementary roof battens might be required.

General Fixing Implications

RHS Steel Supplies advises adhering to the guidelines of the design engineer for the installation of all ceiling battens, roof battens, and top hats. Proper fasteners and specified components are essential as outlined in this manual.

Potential Adverse Conditions

Environmental conditions in the vicinity can influence site conditions and material integrity, including corrosion and wind-related damage. If you intend to install FormBatten™ ceiling battens, roof battens, and top hats within 1 km of corrosive, chemical, or industrial environments, please get in touch with RHS Steel Supplies.

On-site Storage Considerations

For non-immediate storage of RHS Steel Supplies ceiling battens, roof battens, and top hats, secure storage is advised. Elevate all items off the ground and, for prolonged storage, use a slight incline to prevent water accumulation. Extended exposure to adverse weather should be avoided, and waterproof covers are recommended for moisture and rain protection.

Best Practices

RHS Steel Supplies recommends adhering to sound trade practices as outlined in the Australian Standards Handbook HB 39.

Laps & Ends Considerations

Structurally significant laps require a minimum overlap length of 15% of the span (support spacing). For example, a common case is 7.5% at both ends. Two screws are necessary at the support point, and an additional two screws are needed 25-50 mm from both ends of the lap, positioned at the top of the web and bottom flange. This totals to 10 screws per lap.

For all top hat overlaps or non-structural laps, a minimum length of 100 mm is recommended. In these instances, it should not be assumed that these laps possess structural continuity. When joining overlapping top hats, it's vital to align the bottom section with the upper one to ensure proper nesting before and during the fixation process. Laps should be secured through both webs.

End Allowance Considerations

Maintaining a distance of at least 25 mm from the section end is advised for end fastenings. This guideline applies to both the structural end and an internal support. When designing, procuring, or installing materials, accounting for this additional length beyond the span length and laps is crucial when specifying orders or cutting sections.

**Minimum Order Qty is generally 15 Lengths - Contact us if you need less than this Qty.

**Standard lead time, approximately 7 days